Cooling Tower System: Converting Geothermal Energy into Electricity

|

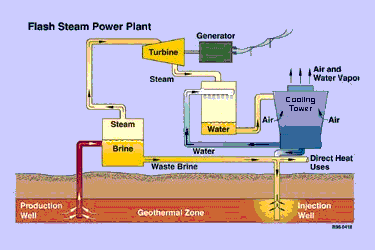

| Example of flash power plant producing electricity |

Heat emanates from the earth's interior and crust generates magma (molten rock). Because magma is less dense than surrounding rock, it rises but generally does not reach the surface, heating the water contained in rock pores and fractures. Wells are drilled into this natural collection of hot water or steam, called a geothermal reservoir, in order to bring it to the surface and use it for electricity production.

The whole process of turning hydro-thermal resources into electricity is based on conversion technologies. That is, there are three basic types of geothermal electrical generation facilities:

binary (it function as closed loop systems that make use of resource temperatures as low as (74°C),

steam (it makes use of a direct flow of geothermal steam), and

flash (uses a mixture of liquid water and steam).

Flash power plant is the most common and it uses a mixture of liquid water and steam.

The type depends on reservoir temperatures and pressures. Each type produces somewhat different environmental impacts.

Example of flash power plant producing electricity

The most common type of power plant to date is a flash power plant (flash steam is the condensation caused by reducing pressure) with a water cooling system, where a mixture of water and steam is produced from the wells. The steam is separated in a surface vessel (steam separator) and delivered to the turbine, and the turbine powers a generator.

A cooling system is essential for the operation of any modern geothermal power plant, because cooling towers prevent turbines from overheating and prolong facility life. Most power plants, including most geothermal plants, use water cooling systems.

Water cooled systems generally require less land than air cooled systems, and are considered overall to be effective and efficient cooling systems. The evaporative cooling used in water cooled systems, however, requires a continuous supply of cooling water and creates vapor plumes. Usually, some of the spent steam from the turbine (for flash- and steam-type plants) can be condensed for this purpose.

Reliability of Geothermal Power Generation

The source of geothermal energy, heat from the earth, is available 24 hours a day, 365 days a year. Solar and wind energy sources, in contrast, are dependent upon a number of factors, including daily and seasonal fluctuations and weather variations. For these reasons, electricity from geothermal energy is more consistently available, once the resource is tapped, than many other forms of electricity.

Examples of Power Plant Size and Applications

Though the size of a power plant is determined primarily by resource characteristics, these are not the only determining factors. Factors that favor the development of larger geothermal plants include things such as cost decreases when larger quantities of materials, including steel, concrete, oil, and fuel, are purchased at one time.

Cooling System

Most power plants, including most geothermal plants, use water-cooled systems – typically in cooling towers.

References/Sources

- Idaho National Lab (INL)

- Wikipedia

- Geothermal Energy Association

- U.S. Department of Energy

|

**********

**********