The following graph illustrates the relationship between the Relative Plan Area (RPA) and Relative Power Consumption (RPC) with respect to increasing Relative Cooling Capacity (RCC), and describes how to double the relative cooling capacity with the same values of all other thermal and size conditions.

RCC

|

RPA

|

RPC

|

1

|

1.00

|

1.00

|

1.1

|

1.15

|

1.33

|

1.2

|

1.31

|

1.73

|

1.3

|

1.48

|

2.20

|

1.4

|

1.66

| |

1.5

|

1.84

|

3.38

|

1.6

|

2.02

|

4.10

|

1.7

|

2.22

|

4.91

|

1.8

|

2.41

|

5.83

|

1.9

|

2.62

|

6.86

|

2

|

2.83

|

8.00

|

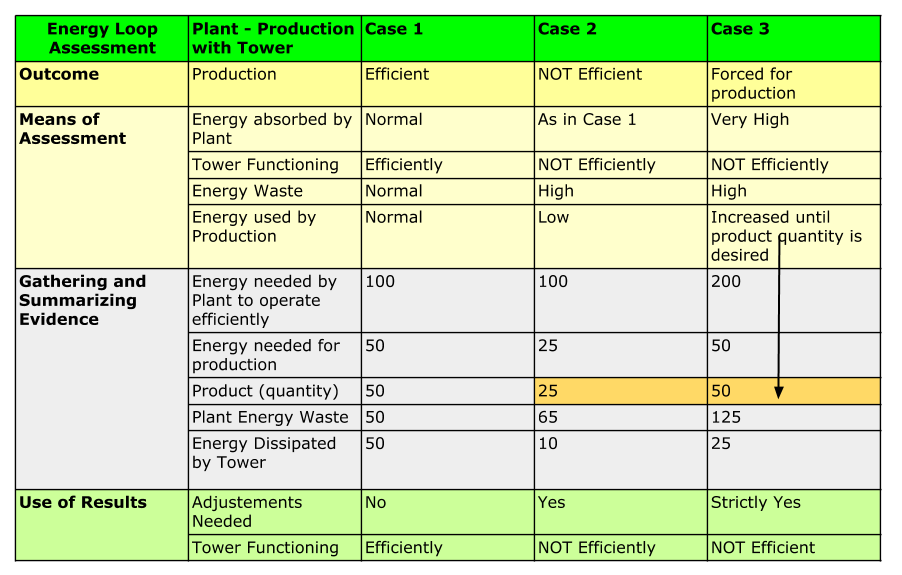

In order to double the capacity (Relative Cooling Capacity) with the same values of all

other thermal and size conditions, the following must be done:

- Increase the surface of the tower by 2 ^ 1.5 times, that is, 2 (double) to the power of 1.5 = 2.83.

The tower must be 2.83 times bigger with the same fan, air flow capacity, etc.

OR:

- Increase the power to 2 ^ 3 times, that is, 2 (double) to the power of 3 = 8.

(verifying the speeds etc.)

References:

Comparative Evaluation of Different Packings

Péter Gosi, Institute far Electric Power Research (VEIKI), Budapest, Hungary

Judith Halasz, Universidade Estadual de Campinas, Sao Paulo, Brazil,

Pal Kostka

.png)